High-risk industries such as oil and gas, chemical processing, marine, power generation, and infrastructure development operate in environments where corrosion is a constant threat. Exposure to moisture, chemicals, extreme temperatures, and pressure can rapidly degrade equipment and structures if left unmanaged. A corrosion risk assessment is a systematic process used to identify, analyze, and prioritize corrosion-related risks before serious damage occurs. Conducting these assessments regularly offers several critical benefits that directly impact safety, cost, and operational efficiency.

1. Enhanced Safety and Accident Prevention

One of the most important benefits of a corrosion risk assessment is improved safety. Corrosion can weaken pipelines, storage tanks, pressure vessels, and structural supports, increasing the likelihood of leaks, collapses, or explosions. By identifying areas most vulnerable to corrosion, organizations can take preventive measures before failures occur. This proactive approach significantly reduces the risk of accidents, protecting workers, surrounding communities, and the environment from potentially catastrophic incidents.

2. Reduced Maintenance and Repair Costs

Unplanned repairs caused by corrosion are often expensive and disruptive. Emergency shutdowns, equipment replacement, and cleanup efforts can quickly escalate costs. A corrosion risk assessment helps organizations prioritize maintenance based on actual risk rather than fixed schedules. By addressing corrosion early, companies can perform targeted repairs, extend equipment life, and avoid costly downtime. Over time, this results in substantial savings and better control over maintenance budgets.

3. Improved Asset Lifespan and Reliability

Industrial assets represent significant investments, and corrosion is one of the leading causes of premature failure. Through a corrosion risk assessment, companies gain a clear understanding of how environmental conditions, materials, and operating practices affect asset integrity. This knowledge allows for better material selection, protective coatings, and corrosion control strategies. As a result, equipment and structures last longer and perform more reliably, supporting consistent production and operational stability.

4. Regulatory Compliance and Environmental Protection

Many high-risk industries are subject to strict safety and environmental regulations. Corrosion-related failures can lead to leaks of hazardous substances, environmental pollution, and legal penalties. Conducting regular corrosion risk assessments helps organizations demonstrate due diligence and compliance with industry standards and regulatory requirements. It also reduces the likelihood of environmental damage, supporting responsible operations and protecting the company’s reputation.

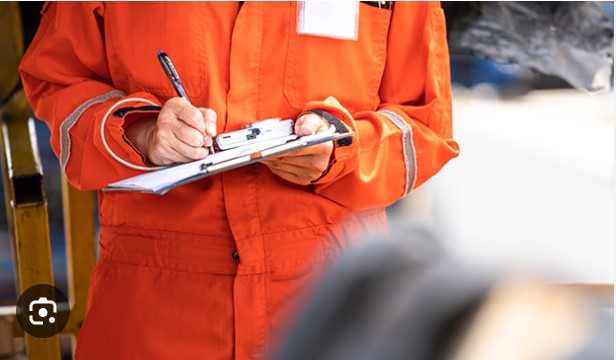

5. Better Decision-Making and Strategic Planning

A corrosion risk assessment provides valuable data that supports informed decision-making. By understanding where risks are highest, management can allocate resources more effectively, plan long-term maintenance strategies, and justify investments in advanced materials or protective systems. This risk-based approach improves planning accuracy and helps organizations move from reactive problem-solving to proactive asset management.

Conclusion

Corrosion may be a natural process, but its impact on high-risk industries can be severe if not properly managed. Conducting a corrosion risk assessment in UAE offers clear benefits, including enhanced safety, reduced costs, extended asset life, regulatory compliance, and improved strategic planning. By identifying and addressing corrosion risks early, organizations can protect their people, assets, and the environment while ensuring long-term operational success.