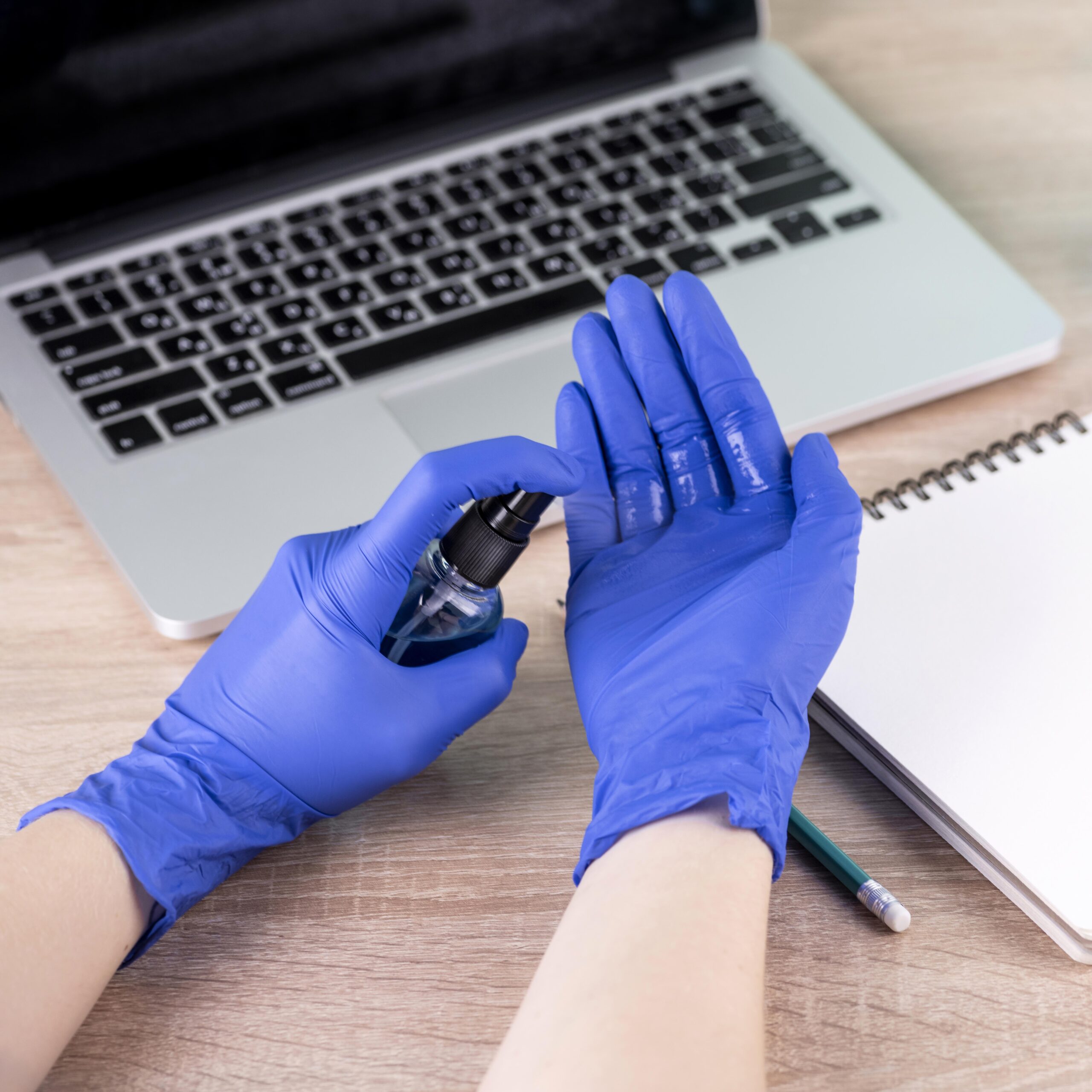

When it comes to workplace safety and hand protection, nitri tech gloves have become the go-to solution for professionals across multiple industries. These nitrile-coated work gloves combine superior grip, durability, and comfort in ways that traditional rubber or leather gloves simply can’t match.

But what makes these gloves so special? And how do you choose the right pair for your specific needs?

What Are Nitri Tech Gloves?

Nitri tech gloves are specialized work gloves featuring a nitrile coating applied over various base materials like nylon, polyester, or cotton. The nitrile coating—a synthetic rubber compound—provides exceptional resistance to oils, chemicals, abrasions, and punctures while maintaining excellent tactile sensitivity.

Unlike disposable nitrile gloves used in medical settings, these industrial-grade gloves are designed for repeated use in demanding environments. The coating typically covers either the palm and fingers or extends to the full hand, depending on the protection level required.

Why Choose Nitrile-Coated Work Gloves?

Superior Grip Performance

The nitrile coating creates a textured surface that dramatically improves grip in both dry and oily conditions. Workers handling small parts, tools, or slippery materials appreciate this enhanced control. Studies show that proper grip reduces hand fatigue by up to 30% during extended work periods.

Chemical and Oil Resistance

Nitrile naturally resists petroleum-based products, hydraulic fluids, greases, and many industrial chemicals. This makes nitri tech gloves ideal for automotive mechanics, machine operators, and maintenance technicians who regularly encounter these substances.

Exceptional Durability

The abrasion resistance of nitrile-coated gloves outlasts cotton or leather alternatives by significant margins. Many users report these gloves lasting 3-5 times longer than standard work gloves, providing better value despite slightly higher upfront costs.

Breathability Matters

Quality nitri tech gloves feature breathable backing materials that prevent excessive sweating. The micro-foam nitrile coatings allow air circulation while maintaining protective barriers—a crucial feature for all-day comfort.

Key Industries Using Nitri Tech Gloves

Manufacturing and Assembly: Electronics assembly, automotive parts, and precision manufacturing require dexterity combined with protection. The thin nitrile coating allows workers to handle small components without sacrificing safety.

Construction and Maintenance: From handling rough materials to operating power tools, construction workers need gloves that withstand punishment. The puncture resistance protects against sharp edges and debris.

Warehousing and Logistics: Package handlers and warehouse workers benefit from enhanced grip when moving boxes and operating equipment. The gloves reduce hand strain during repetitive tasks.

Automotive Services: Mechanics dealing with engine parts, brake systems, and fluids rely on oil-resistant properties. The gloves protect skin from harsh automotive chemicals while maintaining feel.

Understanding Coating Types

Palm-Coated Design

This style applies nitrile coating only to the palm and fingers, leaving the back of the hand uncovered. It offers maximum breathability and flexibility, perfect for light to medium-duty applications in temperature-controlled environments.

Full-Coated Protection

Complete hand coverage provides superior protection against liquids and chemicals. While slightly less breathable, these gloves excel in wet or messy conditions where comprehensive barrier protection is essential.

Foam vs. Sandy Finish

Foam nitrile coatings offer softer feel and better oil grip, ideal for precision work. Sandy or rough finishes provide aggressive grip for handling larger objects or working in extremely oily conditions.

Selecting the Right Fit and Size

Proper fit is non-negotiable for both safety and productivity. Gloves that are too large reduce dexterity and increase accident risk, while tight gloves restrict circulation and cause discomfort.

Measure your hand circumference at the widest part (excluding thumb) and length from wrist to middle fingertip. Most manufacturers provide detailed sizing charts. Remember that different brands may vary slightly in fit.

The glove should feel snug but not restrictive, with fingertips extending just past your natural fingertips—about 1/8 inch beyond is ideal.

Cost vs. Value Analysis

Budget nitri tech gloves typically cost $1-3 per pair, mid-range options run $3-6, while premium industrial gloves can reach $8-12 per pair. However, price shouldn’t be the only consideration.

A $2 glove lasting one week costs more over time than a $6 glove lasting four weeks. Factor in durability, comfort, and productivity impact when making purchasing decisions. Many companies find that investing in quality gloves reduces replacement frequency by 60-70%.

READ ALSO: Big Booty Tech Nerd

Maintenance and Care Tips

Extend glove lifespan through proper maintenance:

Rinse off heavy contamination after each use with mild soap and water. Allow gloves to air dry completely before storage—avoid direct heat sources that degrade nitrile. Store in cool, dry locations away from sunlight and ozone-generating equipment.

Inspect regularly for tears, holes, or coating degradation. Replace immediately if protective integrity is compromised.

Common Mistakes to Avoid

Wrong Application: Using palm-coated gloves for chemical handling or disposable gloves for industrial work compromises safety.

Ignoring Standards: Check that gloves meet relevant safety standards (EN 388 for mechanical risks, EN 374 for chemical protection).

Size Guessing: Always measure and reference sizing charts rather than assuming your size.

Overlooking Comfort: Uncomfortable gloves get removed, defeating their purpose. Prioritize both protection and wearability.

Environmental Considerations

Many manufacturers now offer eco-conscious options using recycled materials for the base liner. While nitrile itself isn’t biodegradable, some companies have developed programs for collecting and recycling used industrial gloves.

Look for brands committed to sustainable manufacturing processes and reduced packaging waste if environmental impact concerns you.

Final Thoughts

Nitri tech gloves represent a smart investment in hand protection that balances performance, comfort, and cost-effectiveness. Whether you’re working in manufacturing, construction, automotive service, or warehousing, there’s a nitrile-coated option designed for your specific needs.

The key is matching glove specifications to your actual working conditions. Consider grip requirements, chemical exposure, abrasion levels, and duration of use. Don’t hesitate to trial different brands and styles—your hands deserve protection that works as hard as you do.